Products

Information

Information

Home> Products Information > V800 SERIES

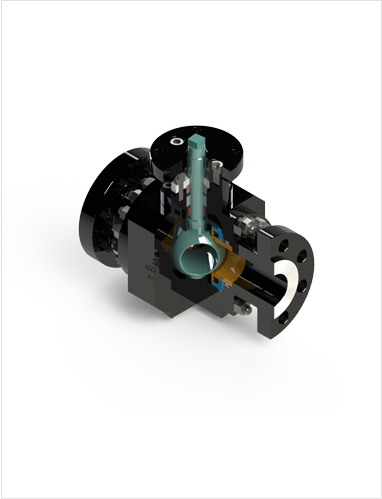

Product Overview

Introduction our recent innovations

- Standard Body Specification : Trunnion Mounted 3-Piece & top entry style

-

standard specification Size 1" to 24"(DN25 … DN600) Rating ANSI 150LBS to 2500LBS, JIS 10K to 63K, PN10 to PN450 Leakage ANSI FCI 70-2, Standard : Class Ⅳ, Option : Class Ⅴ Cv Range 55 to 113,400 Press. Range Up to 6,167 psi (g)

Up to 434 Kg/cm²Temp. Range -150℉ to +1,050℉

-100℃ to +565℃

Option : -320℉ to +1,562℉

-196℃ to +850℃Materials Carbon steel(WCB,WCC),

Stainless steel(CF8,CF8M,CF3,CF3M)

Chrome-moly(WC6,WC9,C12A), other alloysEnd Connections NPT(BSFF), RF/FF/RTJ Flanged, Socket weld, Butt weld Actuators Spring-diaphragm, Cylinder, Electro-Hydraulic Applications On/Off Shore Oil and Gas Production

Subsea Oil and Gas Production

Oil and Gas Storage, Transportation, Gathering Systems

Gas Re-injection Plants, Treatment Plants

LPG and LNG Production, Storage, Transportation

Petrochemical Industry

Metering Systems

Refining Industry

Power Generation

Pulp and Paper Industry

- The ball is fixed and the seat rings are floating, free to move along the valve axis.

- Side load generated by the pressure acting on the ball is absorbed by bearings.

- At low pressure the seat sealing action is achieved by the thrust of the springs acting on the seat rings

- As the pressure increases the fluid pressure pushes the seat rings against the ball.

- The ball and stem are independent to minimize the effect of the side thrust generated by the pressure acting on the ball.

- The electrical conductance continuity between all the metallic components is guaranteed and certified.

- Accurate machining of stem and bonnet sealing surfaces ensures compliance with the most severe pollution control regulations.

- Special “live” seals are available on request.

- Two independent floating seat rings assure the bi-directional tightness of the valve.

- The seats are carefully designed to minimize the torque required to operate the valves without losing sealing power,

which is assured from zero differential pressure to the valve’s maximum rated pressure.

- Self-relieving seats are supplied as a standard feature. Double piston or combination seats (self-relieving/upstream, double piston/downstream) can be supplied on request.

Our Company

Our Company